Pharmaceutical fluid handling equipment includes a wide variety of equipment, such as (metering) pumps, capsule equipment (filling, sorting), mixing equipment, thermal processing equipment (coolers, chillers, dryers, heat-exchangers), (x-ray) inspection systems, and tanks for holding liquids.

To guarantee precise manufacturing and formulation development, nearly every process can be automated. Resultantly, there is a piece of pharmaceutical manufacturing equipment involved in every processing step.

Hygienic fluid handling systems

Product integrity is crucial in the pharmaceutical industry. The highest sanitation standards must be observed for a product to maintain the same characteristics in every production batch.

In pharmaceutical processing industries, measuring and controlling the flow of liquids and gases demands exceptional process instrument performance and networkability.

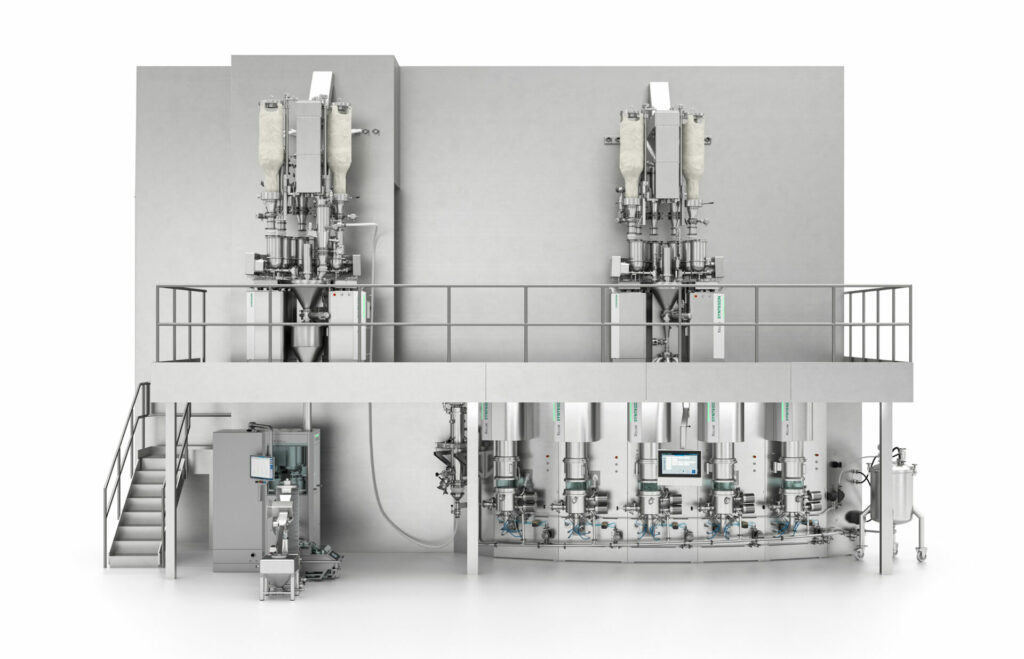

Process systems for the preparation of pharmaceutical liquids

Production of pharmaceutical liquids is carried out in temperature-controlled stainless-steel tanks with stirring units under the addition of chemicals with or without nutrient solutions.

A complete understanding of the pharmaceutical production process is critical for the correct design. Clear definition, assessment, monitoring of essential parameters directly affecting product quality are the baseline for applying suitable process systems granting complete in-line and at-line quality control.

The vast majority of liquid pharmaceutical solutions require a variety of tankage, piping, and ancillary equipment for fluid mixing, filtration, transfer, and related activities. Suspensions, ointments, and other similar products, including the preparation of the solutions for freeze-dried products, can be manufactured in the same or very similar equipment.